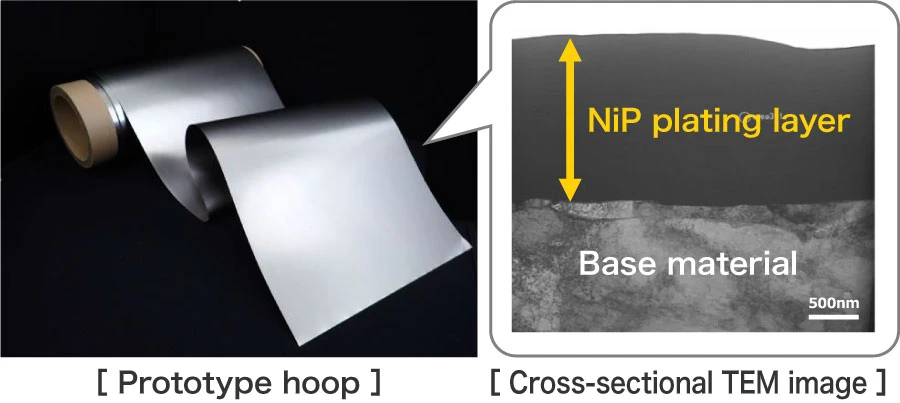

Electrolytic NiP plating is produced roll-to-roll

- Supplied as hoop plating

- Can be plated onto thin substrates

- Can be plated on a variety of substrates

- Plating thickness can be controlled on front and back sides

- Single-sided plating also available

Characteristics

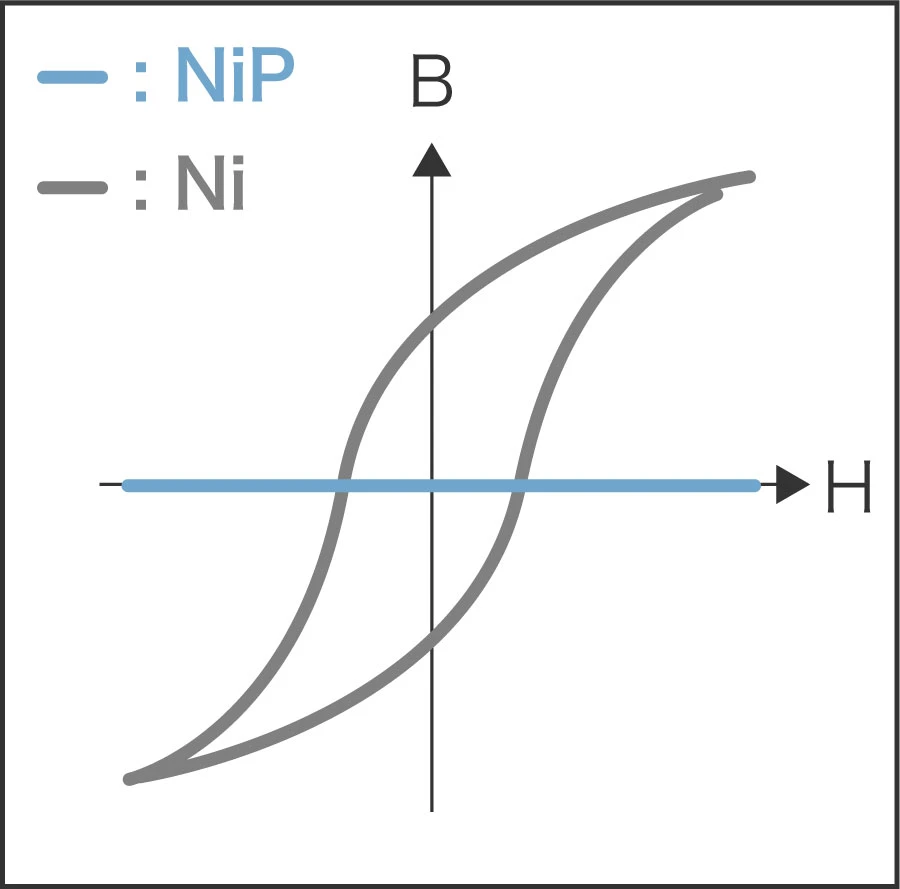

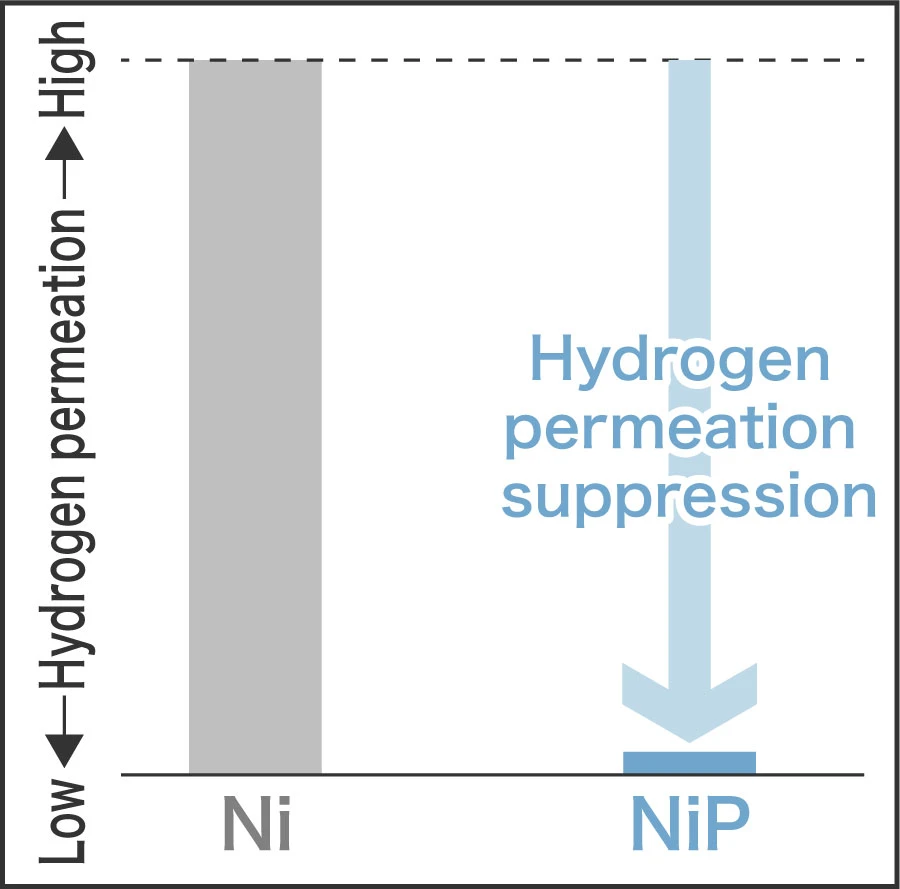

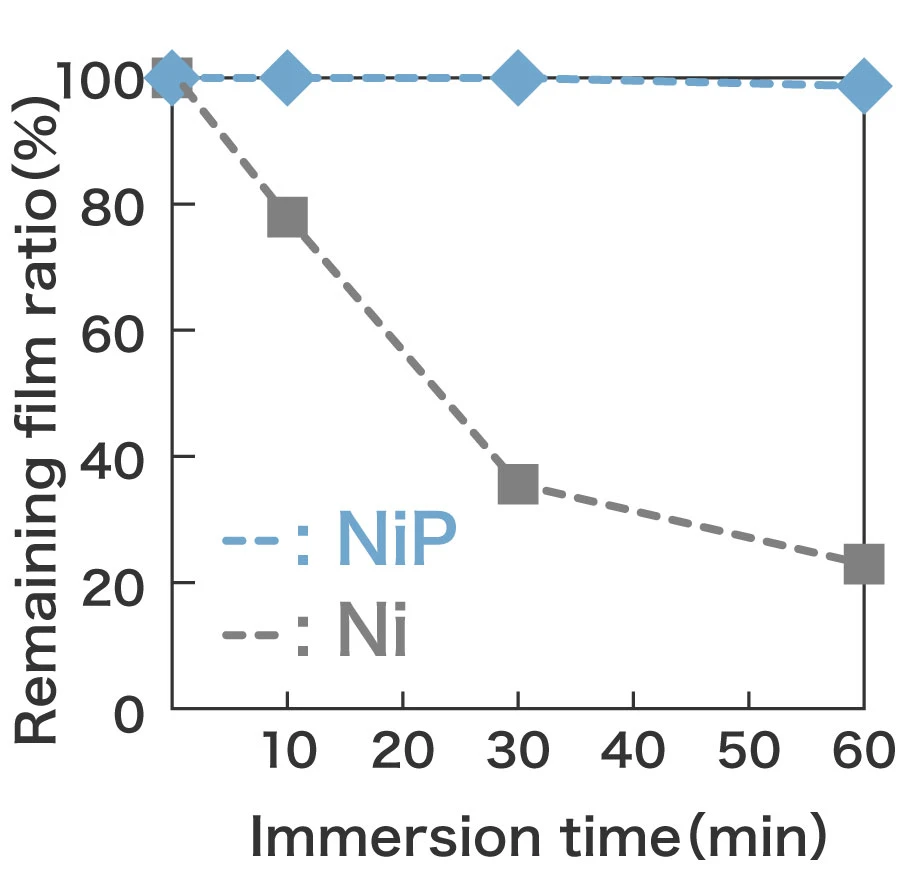

Comparison of electrolytic NiP plating (P content: 14 wt%) versus Ni plating

Non-magnetic

(P content: 10+ wt%)

(P content: 10+ wt%)

(Compared to Ni: About 100 times more)

Excellent acid resistance

(Compared to Ni: At least 40 times more)

Examples of use

Electric and electronic parts

Improves corrosion resistance of non-magnetic parts!

Fuel cell/hydrogen-related equipment

Fuel cell/hydrogen-related equipment

Range of possible prototypes

| Item | Scope of application |

|---|---|

| P content | Max. 14wt% |

| NiP film thickness | ~ μm |

| Type of base material | Steel sheet, copper sheet, stainless steel sheet, etc. |

| Width of base material | Max. 230mm |

| Thickness of base material | Min. 35μm |

Please discuss your any other needs with us.