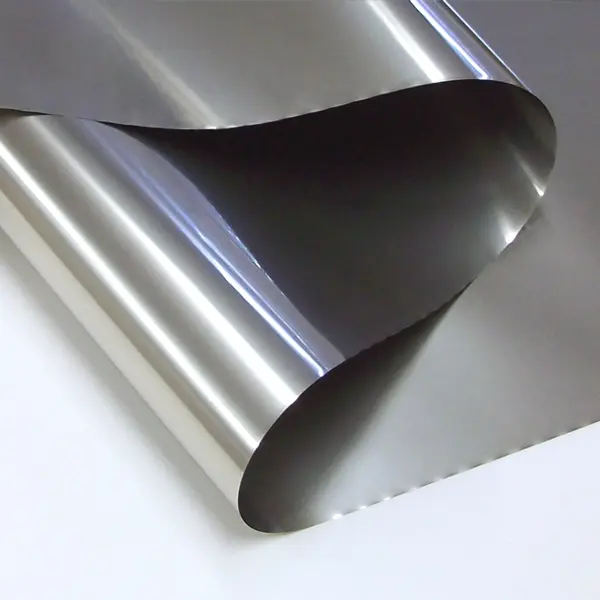

We offer an abundant lineup of electro-galvanized steel sheets from 50 µm to 1.2 mm in thickness, featuring attractive surface finishes, scratch resistance, workability, paintability, solder wettability, conductivity, and other functional properties!

Surface-treated steel sheets are used for various applications. Among these, galvanized steel sheet accounts for the largest market share. Galvanized steel sheet can be broadly classified into hot-dip galvanized steel sheet and electro-galvanized steel sheet (JIS G3313 EG). Toyo Kohan’s Silver Top product has been a leader in the field of electro-galvanized steel sheets. Silver Top has a number of superior features unmatched by any other product, and has been used in a wide range of applications ever since production started in 1967, earning it an excellent reputation.

Corrosion resistance

A self-sacrificing corrosion resistance feature, unique to Zn plating, protects steel sheets from rust. Corrosion resistance is further improved by Zn-Co-Mo composite zinc plating.

Versatility

A diverse lineup of products is available, with specialized functions depending on intended use.

Available in ultra-thin widths

Rolling technology enables production starting at 50 µm (metal foil).

Product Family

We can provide a wide variety of functions that exceed the expectations of electrogalvanized steel sheet.

Composite Galvanized Products

Unpainted Silver Top

Features such as a beautiful metallic appearance, high corrosion resistance, wear resistance, low paper friction, scratch resistance and fingerprint resistance, have led to an excellent reputation for this unpainted galvanized steel sheet for many years.

HE-71

Functions:Corrosion resistance/Conductivity/Smooth surface/Scratch resistance/Fingerprint resistance

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

HE-72

Functions:Corrosion resistance/Smooth surface/Scratch resistance/Fingerprint resistance

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

HE-73

Functions:Corrosion resistance/Wear resistance/Smooth surface/Scratch resistance/Fingerprint resistance

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

Silver Top for painting

This product has superior paint adhesion and a high grade paint finish that can only be achieved with electroplating. This has led to an excellent reputation for this product ever since it was put on sale because of the combination of these factors together with our unique ability to make 0.11 thickness sheets and the highly workable substrates we use.

TE-90

Functions:Paint adhesion

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

TE-91

Functions:Paint adhesion Heat resistance

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

Black Silver Top

Made with our original production methods, this product has the necessary properties to replace painted steel sheet, such as a greatly improved black appearance, the same properties as our unpainted Silver Top and heat dissipation properties only possible with black steel sheet.

BEP22

Functions:Corrosion resistance/Smooth surface/Fingerprint resistance/Heat dissipation

Zn quantity:3 to 20g/m²

Sheet thickness range:0.2 to 1.6mm

Consult for thicknesses from 0.15 to 0.19

BEX28

Functions:Conductivity/Smooth surface/Fingerprint resistance/Heat dissipation

Zn quantity:3 to 20g/m²

Sheet thickness range:0.2 to 1.6mm

Consult for thicknesses from 0.15 to 0.19

Pure Galvanization

Silver Top for soldering

This product has a history of over ten years as a steel sheet for lead-free soldering. This product has the properties required for electronic parts, such as good solder adhesion with lead-free solder and deactivated flux, whisker resistance, and a high shielding ability together with high surface conductivity.

ZE-35

Functions:Ecological type/Conductivity/Solderability

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

Consult for thicknesses from 0.11 to 0.14

Black soldering Silver Top

ZEB25

Functions:Ecological type/Conductivity/Solderability Heat/dissipation

Zn quantity:3 to 20g/m²

Sheet thickness range:0.15 to 1.2mm

Steel Foil(SF)

This is an ultra-thin galvanized steel sheet from 50 to 100 μm thickness that is made with our ultra-thin rolling technology that is represented by our shadow mask material. Our regular Silver Top can be used for thicknesses of 110 μm and higher.

SF-Z

Functions:Chromate/Corrosion resistance

Zn quantity:3 to 20g/m²

Sheet thickness range:0.05~0.10mm

SF-42

Functions:Ecological type/Corrosion resistance

Zn quantity:3 to 20g/m²

Sheet thickness range:0.05~0.10mm

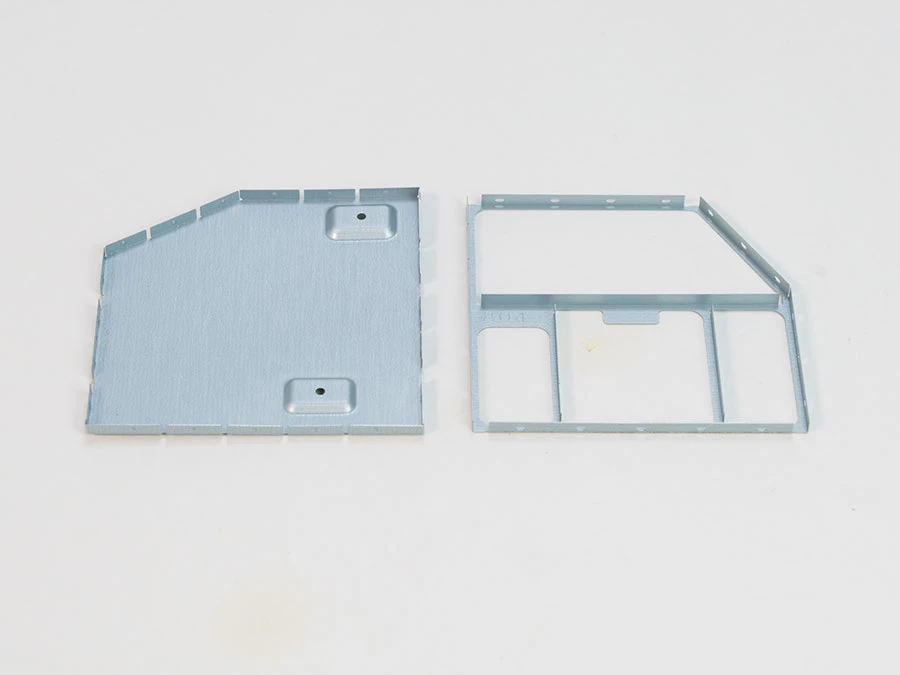

Applications

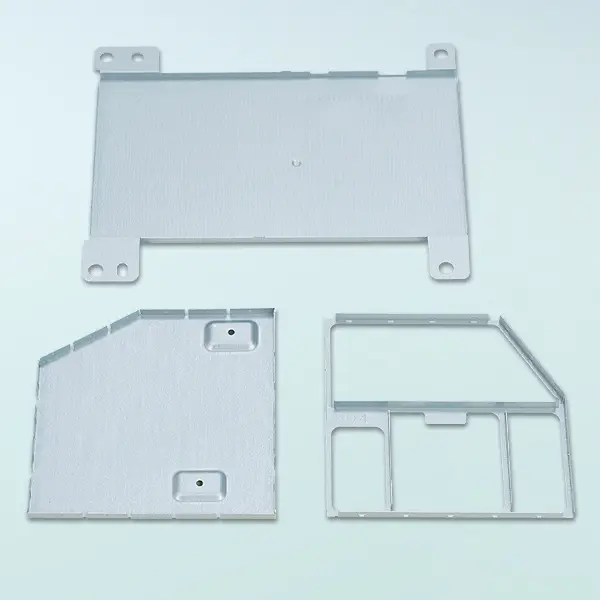

- Precision equipmen

- Automotive part

- LCD bezel parts

- Electrical and electronic parts

- Paper feeding parts

Its golden color and beautiful appearance, which overturns conventional notions of galvanized steel sheet, makes it suitable for various cases, covers, panels, and other design applications. Using our superior rolling technology, we also provide ultra-thin materials (SF) at 50 µm, which is the thinnest galvanized steel sheet ever produced, helping our customers reduce costs as a replacement for copper foil, nickel silver foil, and phosphor bronze foil. We have also made efforts to diversify by supplying scratch-resistant steel sheets that enables stamping of small parts and steel sheet with mechanical properties suitable for machining, thus improving customer yields.

The price of stainless steel has been rising in line with the recent surge in the price of nickel. To replace stainless steel, we have developed High-strength Silver Top, a high-strength steel sheet with various types of zinc plating, which is much stronger than regular cold-rolled steel sheet, has added elasticity, and can be stretched. It is being used as a new material in electrical and electronic components to reduce costs.

Coating-free Silver Top

Silver Top for painting

Silver Top for soldering

(power supply parts, etc.)

(car AV equipment)

(car AV equipment)

Black Silver Top

SF

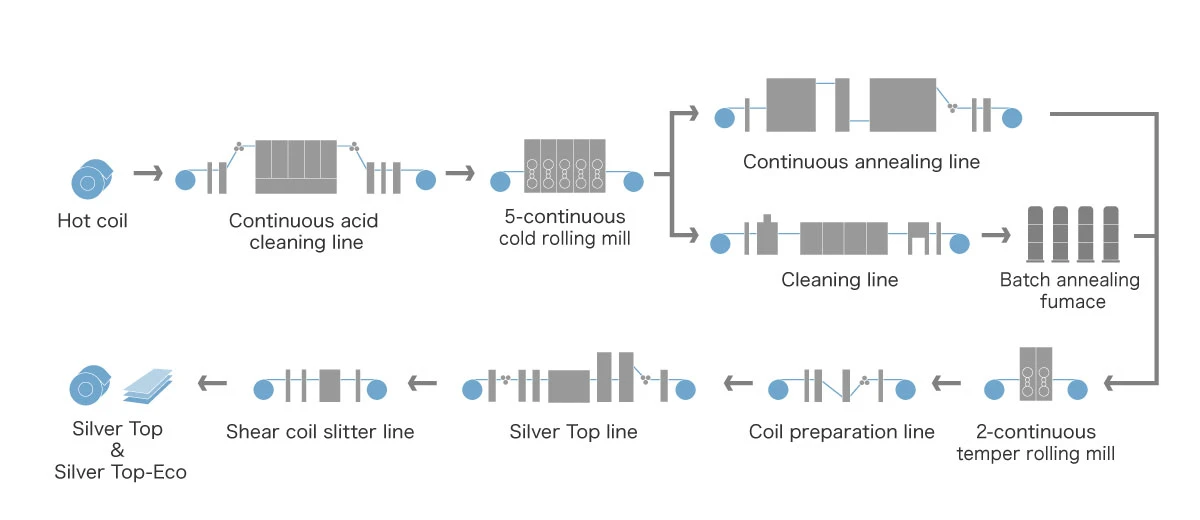

Manufacturing process

Silver Top is manufactured under strict quality control using state-of-the-art equipment and techniques to ensure the right characteristics for each application.

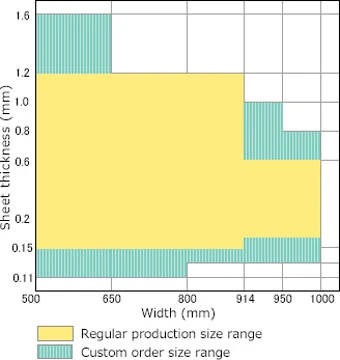

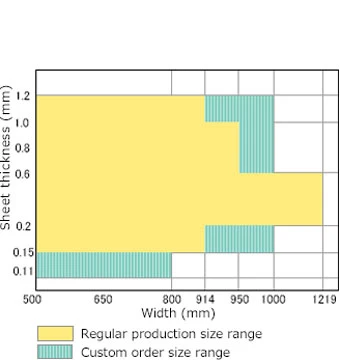

Available Sizes

| Specifications | Producible sizes(mm) | Custom sizes(mm) | |||||

|---|---|---|---|---|---|---|---|

| Sheet thickness | Width | Sheet thickness | Width | ||||

| MIN. | MAX. | MIN. | MAX. | ||||

| Unpainted Silver Top and Silver Top for painting | – | – | – | 0.110 | 500 | 800 | |

| – | 500 | 914 | 0.12 to 0.149 | 500 | 1000 | ||

| 0.15 to 0.199 | 500 | 950 | 0.15 to 0.199 | – | 1000 | ||

| 0.20 to 0.59 | 500 | 1000 | 0.60 to 0.80 | – | 1000 | ||

| 0.60 to 1.20 | 500 | 950 | 0.81 to 1.00 | – | 950 | ||

| – | 500 | 914 | 1.21 to 1.60 | 500 | 650 | ||

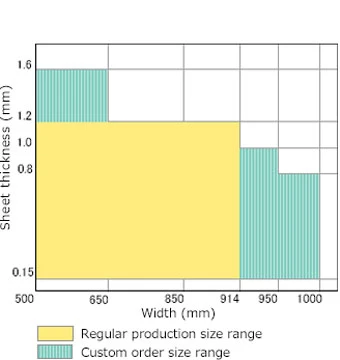

| Silver Top for soldering | – | – | – | 0.11 to 0.149 | 500 | 800 | |

| 0.15 to 0.199 | 500 | 914 | 0.15 to 0.199 | – | 1000 | ||

| 0.20 to 0.60 | 500 | 1219 | – | – | – | ||

| 0.61 to 1.00 | 500 | 950 | 0.61 to 1.20 | – | 1000 | ||

| 1.01 to 1.20 | 500 | 914 | – | – | – | ||

| Black Silver Top | 0.15 to 1.20 | 500 | 914 | 0.15 to 0.80 | – | 1000 | |

| – | – | – | 0.81 to 1.00 | – | 950 | ||

| – | – | – | 1.21 to 1.60 | 500 | 650 | ||

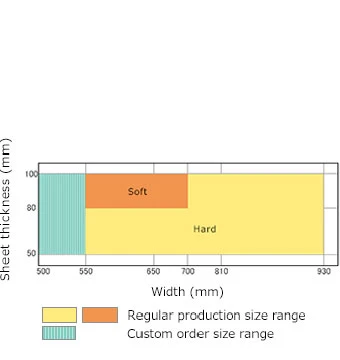

| SF-Z | Hard | 50 to 100μm | 550 | 930 | 50 to 100μm | 550 or less | – |

| Soft | 80 to 100μm | 550 | 700 | 80 to 100μm | 550 or less | – | |

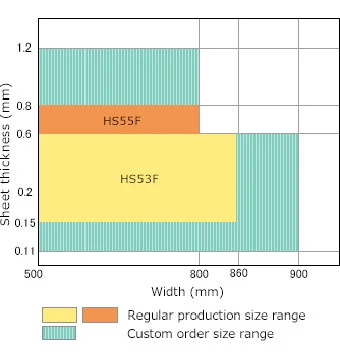

| High-strength Silver Top (for machining) | HS55F | – | – | – | 0.11 to 0.149 | 500 | 900 |

| 0.15 to 0.59 | 500 | 860 | 0.15 to 0.59 | – | 900 | ||

| HS53F | 0.60 to 0.80 | 500 | 800 | 0.81 to 1.20 | 500 | 800 | |

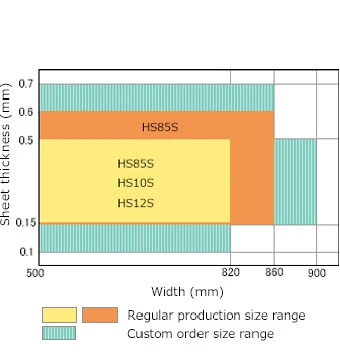

| High-strength Silver Top (for springs) | HS85S | – | – | – | 0.11 to 0.149 | 500 | 820 |

| 0.15 to 0.59 | 500 | 860 | 0.15 to 0.59 | – | 900 | ||

| – | – | – | 0.61 to 0.70 | 500 | 860 | ||

| HS10S HS12S | 0.15 to 0.49 | 500 | 820 | – | – | – | |

Standards

Silver Top and Silver Top-ECO are manufactured under strict quality controls based on standards comparable to JIS G 3313.

Types of substrates and temper categories

| Equivalent JIS standard | Toyo Kohan Standard | Mechanical properties (reference) | Remarks | ||||

|---|---|---|---|---|---|---|---|

| Tensile strength | Extension | Hardness | |||||

| Type | Temper category | Temper symbol | Temper symbol | (N/mm²) | (%) | HR-30T | |

| SPCC | Standard | S | SN、SO、SE | 270 or higher | 25 or higher | 58 or lower | |

| 1/8 hardness | 8 | SUS | 290 to 410 | 25 or higher | 48 to 63 | ||

| 1/4 hardness | 4 | SU4、SU5 | 370 to 490 | 10 or higher | 58 to 68 | ||

| 1/2 hardness | 2 | 2 | 440 to 590 | – | 63 to 74 | ||

| Hard | 1 | 1 | 550 or higher | – | 71 or higher | ||

| SPCD | Standard | S | SD、D-CA | 270 or higher | 28 or higher | 58 or lower | |

| HS53F | 420 to 550 | 20 to 35 | 61 to 71 | High-strength steel sheet | |||

| HS55F | 520 to 650 | 15 to 35 | 65 to 75 | ||||

| HS85S | 780 to 950 | 5 to 23 | 75 to 83 | ||||

| HS10S | 850 to 1100 | 3 to 20 | 78 to 85 | ||||

| HS12S | 1100 to 1300 | 0 to 15 | 82 to 90 | ||||

Galvanized Coverage(Per Side)

| Nominal Coverage(g/m²) | Minimum Coverage(g/m²) | Comparable Plated Thickness(μm) |

|---|---|---|

| 3 | 2.5 | 0.4 |

| 5 | 4.25 | 0.7 |

| 10 | 8.5 | 1.4 |

| 15 | 12.75 | 2.1 |

| 20 | 17 | 2.8 |

Reference:Comparable JIS Codes

Type Codes and Applicable Display Thicknesses(Using Cold Rolled Substrates)

| Code Types | Applicable Display Thickness(mm) | Cold Rolled Substrate Type Codes Used | Uses |

|---|---|---|---|

| SECC | More than 0.3, Less than 3.2 | SPCC | General Purpose |

| SECD | SPCD | For Ties |

Compatible display thickness from 50μm to 1.6mm.

Chemical Process Types and Codes

| Chemical Process Types | Code |

|---|---|

| Chromate Process | C |

| Phosphate Process | P |

| Chromate Free Process | NC |

| Chromate Free Phosphate Process | NP |

| Non Processed | M |

Compatible chemical processes are NC, NP and M.

Lubrication Types and Codes

| Lubrication Types | Code |

|---|---|

| Lubrication | O |

| Non Lubrication | X |

Please inquire separately for oil types.

Galvanized Coverage Label Codes

| alvanized Coverage Label Codes | Minimum galvanized coverage(g/m²) | Standard galvanized coverage(g/m²) |

|---|---|---|

| ES | – | – |

| EB/EB | 2.5 | 3 |

| E8/E8 | 8.5 | 10 |

| E16/E16 | 17 | 20 |

| E24/E24 | 25.5 | 30 |

| E32/E32 | 34 | 40 |

| E40/E40 | 42.5 | 50 |

The table above is for uniform thickness plating.

Compatible standard galvanized coverage is 5 to 30g/m2 for each 5g/m².

List of Compatible JIS Code Comparable Products

| Comparable JIS Codes | Comparable Product Specification Codes |

|---|---|

| SECC-NC | HE-71、HE-72、HE-73、ZE-35、ZEB25、BEP22、BEX28 |

| SECC-NP | TE-90、TE-91 |

| SECC-M | Non Processed Silver Top |

| SECD-NC | HE-71、HE-72、HE-73、ZE-35、ZEB25、BEP22、BEX28 |

| SECD-NP | TE-90、TE-91 |

| SECD-M | Non Processed Silver Top |

No JIS Code comparable products containing the following hexavalent chrome are manufactured because the Silver Top series is completely chrome free. (SECC-C, SECC-P, SECD-C, SECD-P)