Hi-Pet is a safe, environmentally friendly material used for beverage cans.

Hi-Pet is a film-laminated steel sheet originally developed by us. One of the application of this product is the TULC can. Making cans from this material means that painting and cleaning processes can be eliminated, resulting in environmentally friendly cans with significantly reduced CO2 emissions and zero wastewater. Application for food cans and 18-liter cans are also expected.

“TULC can” stands for Toyo ULtimate Can. Developed by Toyo Seikan Co., Ltd.

Environment friendly

Lacquering process can be eliminated, which helps to reduce CO2 emissions.

Excellent barrier properties

Its excellent barrier properties effectively inhibit steel corrosion and protect the contents.

Excellent workability

Aids lubrication when forming, offering excellent formability.

Our Products

Hi-Pet

- The film’s surface allows for attractive painting or printing.

- Laminate substrates can be made not only of steel sheets (TFS, tin plate) but also of aluminum sheets.

- These conform to the Food Sanitation Act.

Applications

From industry standard to state-of-the-art, our products are used in daily life throughout the world.

- Beverage cans (TULC, aTULC)

- Can lids

- Metal caps

- Canning jars (2-piece cans)

- 18-liter cans

- Candy tins

- Spray cans

- Stationery, office supplies

Examples!

Beverage cans(Hi-Pet)

From ice-cold cans of juice enjoyed in the hot summer sun to refreshing canned coffee enjoyed during a quick break, if the bottom of the can is white, it means the can was made using Toyo Kohan’s environmentally friendly material.

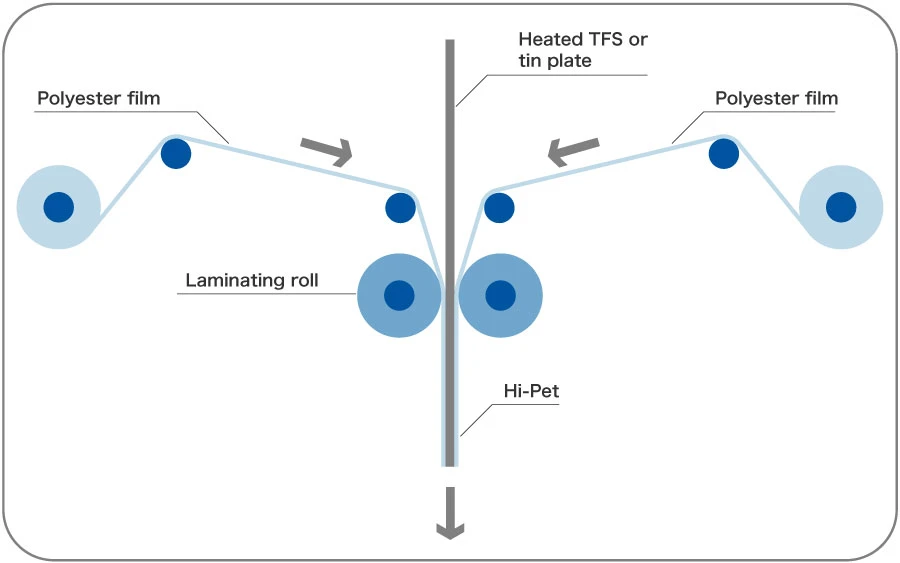

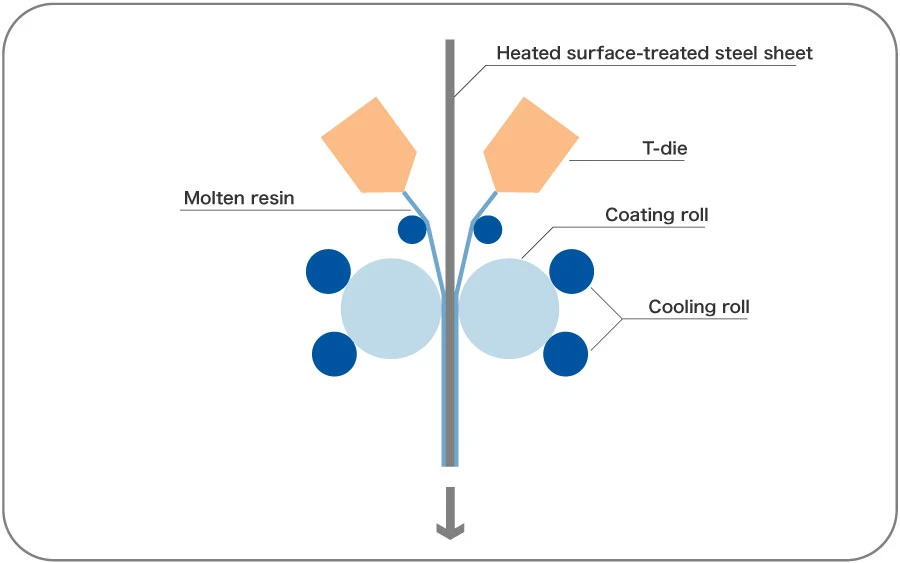

Manufacturing process

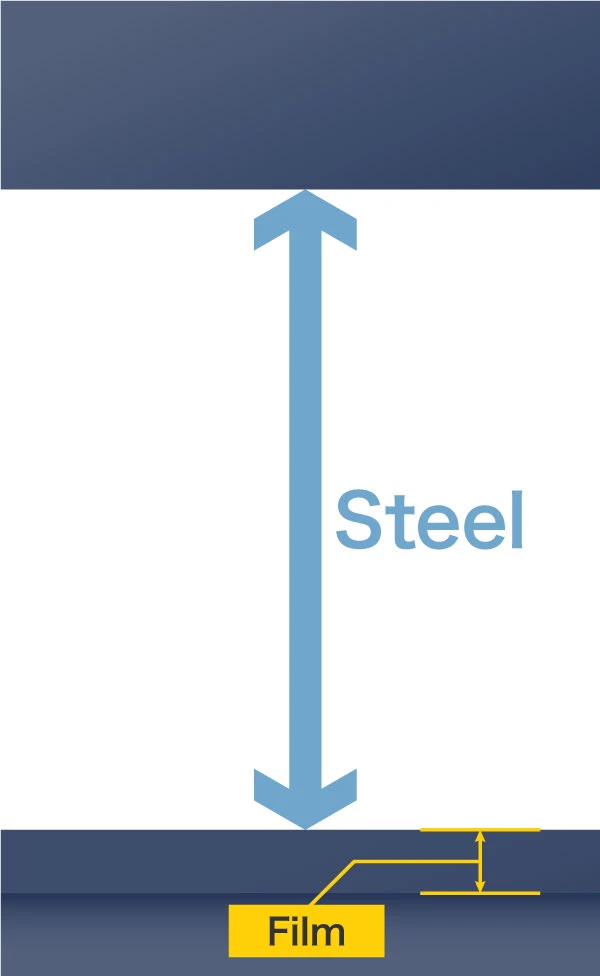

Hi-Pet requires a rigorously controlled manufacturing process to achieve strong adhesion between the film and steel plate.

Using a high-level clean room environment with the latest quality assurance measuring instruments, for achieving stable quality.

Properties

- Can be used for various drawn can body materials, aerosol cans, caps, 18-liter cans, etc.

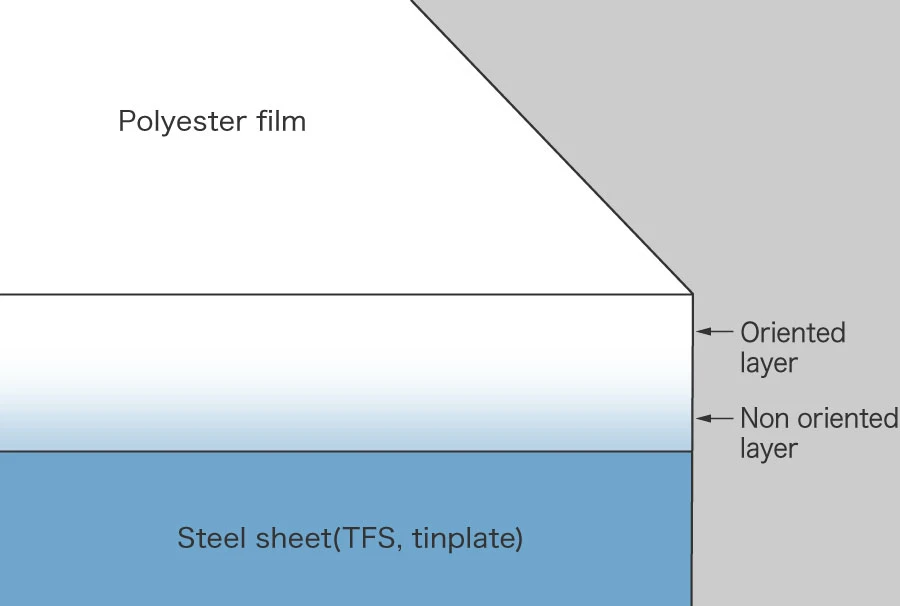

- Polyester film is laminated onto heated TFS or tin plate.

- The laminated polyester layer consists of biaxially oriented and non-oriented layers.

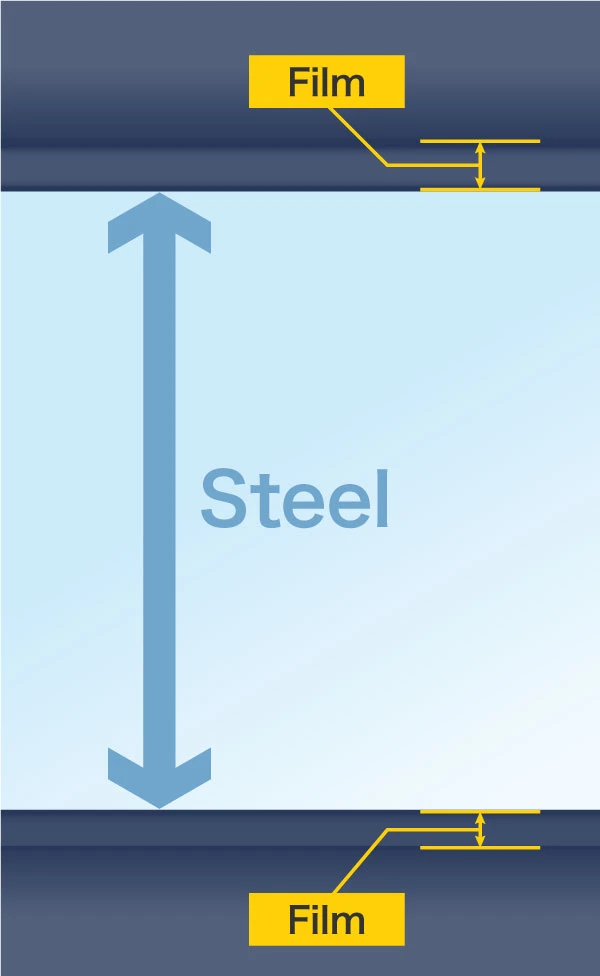

- Both single-sided and double-sided lamination are possible.

- White polyester film can also be laminated.

- If laminated steel sheets are heated for painting or printing processes, etc., please consult with us.

| Comparison of properties | Laminated steel sheet Hi-Pet | Examples | ||

|---|---|---|---|---|

| Polypropylene laminated steel sheet | Polyethylene laminated steel sheet | |||

| Melting point of laminating resin(heat resistance) | 250 to 260°c | 150 to 170°c | 100 to 130°c | |

| Chemical resistance | Acids | ○ | ○ | ○ |

| Alkalines | × | ○ | ○ | |

| Organic solutions | ○ | ○ | ○ | |

| Reaction with contents (beverages, paint, etc.) | None | Adsorption | Adsorption | |

Available Sizes

Size availability depends on the combination of specifications of film and substrates (thickness, width, temper etc.).

Ask us about availability of each size.

| Item | Specifications | ||

|---|---|---|---|

| Substrate | Type | Tinplate, TFS, aluminum | |

| Film | Film thickness | Clear film | 12 to 40μm |

| White film | 13 to 30μm | ||

| Laminate | Laminate surface | One side, both sides | |

Coil

| Item/Substrate type | Substrate thickness(mm) | Product width(mm) |

|---|---|---|

| Tinplate | 0.15 to 0.60 | MAX:1,050 |

| TFS | 0.15 to 0.38 | MAX:1,200 |

| 0.38 to 0.60 | MAX:900 |

Contact us for more details.

Sheet

| Item/Substrate type | Substrate thickness(mm) | Product width(mm) | Product cutting length(mm) |

|---|---|---|---|

| Tinplate | 0.155 to 0.420 | 450 to 900 | 555 to 1,105 |

| TFS | 0.155 to 0.380 | 450 to 1,000 | |

| 0.380 to 0.420 | 450 to 900 |